|

GeMA

The GeMA main application

|

|

GeMA

The GeMA main application

|

Conceptually, our example simulation problem, described by the model data created on previous sections, can be solved by several different numerical methods. As seen on section I - Basic GeMA concepts, the solution method describes how the problem should be solved. In our heat conduction example, its role will be to guide the GeMA framework into solving the heat equation by the finite element method.

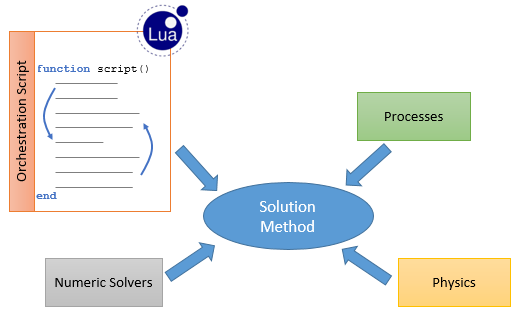

For a GeMA simulation, the solution method is composed of four main entities (Figure 13):

In a broad way, the execution of a simulation can be seen as being composed by the execution of a series of processes that exchange data between them, cooperating to achieve the desired final result. Among others, the GeMA framework includes processes for:

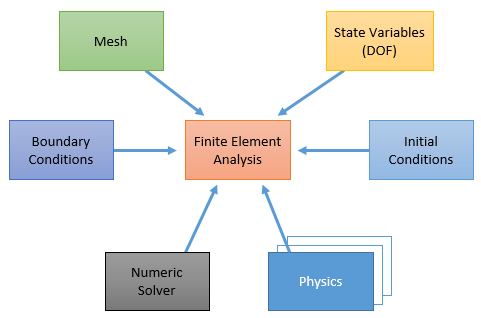

The FEM process implements the analysis method required for the solution of our example problem. The main entities involved in a finite element analysis are given in Figure 14. They are:

Steps needed in a FEM analysis are basically the same, independently of the equations being solved. The distinction between a stress and a temperature analysis are basically the equations that are solved to calculate local element matrices. In GeMA, the global steps of a FEM analysis are the process, while the routines used to calculate local element matrices are the physics.

Numeric solvers are implemented in GeMA by plugins. The standard numeric solver uses the Armadillo linear algebra package, that in turn uses the SuperLU library to solve symmetric or unsymmetric sparse linear systems of equations through a direct LU decomposition method.

The code above declares the numerical solver that will be used in our example problem. It simply selects the Armadillo solver plugin (typeName = "ArmadilloSolver"), which doesn't needs any further configuration options.

Physics are also implemented in GeMA by plugins. The code below declares the thermo physics object required by the FEM process to solve the heat equation. It selects the standard thermo plugin (typeName = "ThermoFemPhysics") and fills some required fields for FEM processes.

The type field tells GeMA that this is indeed a physics suitable for use with the FEM process. The mesh field binds it to the mesh over which the fem process will be executed. If several physics are needed, all of them must reference the same mesh. Finally, the boundaryConditions field binds the physics to the set of boundary conditions applied to the problem solution. This field is a table and can list more than one condition.

These fields are common to every FEM physics. On our example problem, no other specific options are needed. Available options can be found on the thermo plugin documentation and include, for example, options to enable heat flux recovery or internal heat generation.

The orchestration script is always given by the ProcessScript() function. Running a GeMA simulation is equivalent to executing this Lua function inside the framework environment. Inside the orchestration script, processes are executed by calling them as Lua functions, independently if they were defined in C++ by a plugin or by a user given Lua function. The orchestration script for the steady state simulation is pretty simple and given below.

The first process call, fem.solve(), executes a linear FEM analysis as a single step. It receives as parameters the set of physics objects used in the simulation, identified by their names, and the numeric solver used to solve the resulting linear equation system. This function can optionally receive other tables with additional process options, as can be seen in the linear fem process documentation.

The call to the io.printMeshNodeData() process simply prints data associated to mesh nodes. The first parameter consists of the mesh name, followed by a table that includes the set of node attributes and state variables that should be printed. The special name coordinate asks that an additional column with node coordinates should also be printed. The last parameter is a table with printing options. The eval_functions option is needed to tell the process that the functions tied to the Err attribute should be evaluated and the resulting value printed. Without this flag, the function name would be printed instead. More options can be found on the io process documentation.

Finally, the call to the io.saveMeshFile() is responsible for saving data to a file. It receives as its first parameter the mesh name, followed by the file name, its type ("nf" means that a neutral file will be created) and by a table with the set of node attributes and state variables to be saved, much as the one passed to the print process.

The VtkLib set of auxiliary functions can be used to write results in the Vtk file format, for post-processing with the Paraview application. The library is loaded with the use of the dofile() function and the file saved by the call to vtkLib.saveMeshFile().

For the transient case, another script is needed. For greater flexibility, the outer time loop is given by the orchestration and the FEM process is called once for each time step. Its code is given below.

At line 4, the fem analysis solver is initialized by a call to the fem.initTransientSolver() process. Its parameters are the same as the ones passed to fem.solve(), but instead of processing the simulation, this call now tells the FEM process that a transient simulation will begin and that further calls to run simulation steps will be made. The process returns a handle that stores the iterative simulation context and that should be passed as a parameter in further calls to the FEM process. This handle is stored on the solver local variable.

On lines 6 through 8, the script defines the used time step (1ms) and the simulation duration (0.2s) and calculates the number of needed time steps nsteps. In line 11, the io.prepareMeshFile() call initializes the file that will receive simulation results at each time step. Its parameters are the same as the ones passed to io.saveMeshFile() in the previous script. It also returns a handle to be passed while adding results to the file. The VtkLib is also loaded.

Line 16 is the main simulation loop, iterated nsteps times. It repeatedly executes a simulation step by calling fem.transientStep(), passing as parameters the handle obtained at line 4 and the elapsed simulation time between this call and the previous one. The loop is completed by saving the current results to file by calling io.addResultToMeshFile(), and by saving a new Vtk file for this time step (in Vtk, each step must be saved to a different file with a numeric suffix added automatically by vtkLib.saveMeshFile()). Finally, after the simulation ended, the neutral file result file is closed by a call to io.closeMeshFile().

The call to setCurrentTime() at line 19 is not a process call, but an internal GeMA function used to tell the framework about the current time. This function is not really needed in this simulation since no user functions depend on time parameters. It is included here as a good practice.

Go to the next section, previous section or return to the index.

1.8.15

1.8.15